Borehole Shear Tester

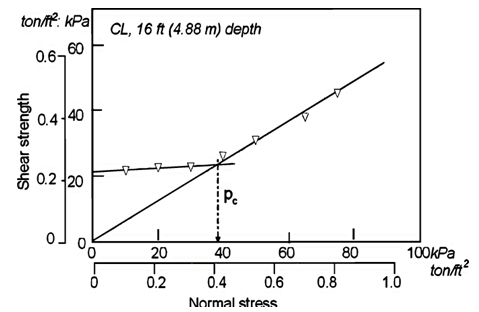

In 1773 a French engineer working in Africa noticed that clay soil can stand in a vertical bank whereas sand slides down. He therefore reasoned that there must be two strength components in soils, cohesion (in clays) and internal friction (in sands). This simple observation was a turning point for geotechnical engineering. The engineer’s name was Charles Coulomb, later of electricity fame.

Cohesion and internal friction both occur in most soils, so measuring one without the other gives only half of the story.

There are two ways to measure soil shear strength:

- Poke the soil with your thumb and take a guess. (This actually can be quite sophisticated but a guess is still a guess.)

- Measure it.

There are two approaches to measuring soil shear strength:

- Bore a hole, sample the soil, and take samples to a laboratory for testing.

- Bore a hole and test the hole. Which do you suppose is more convenient, faster and less damaging to the soil?

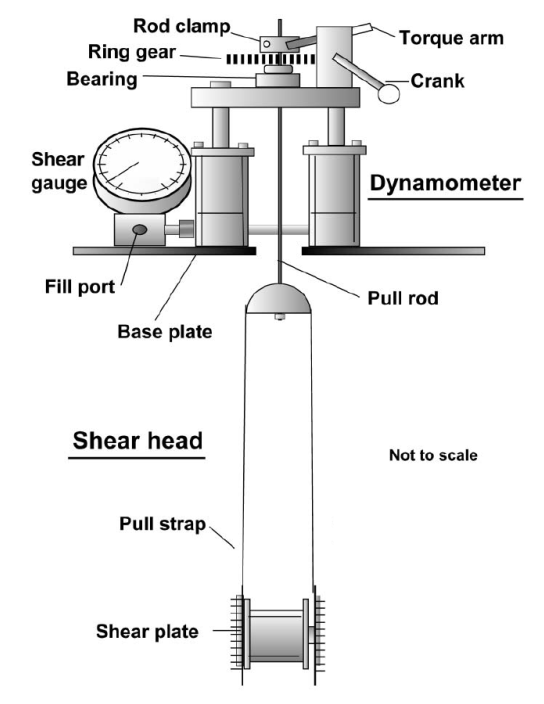

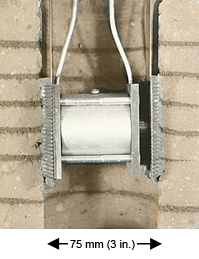

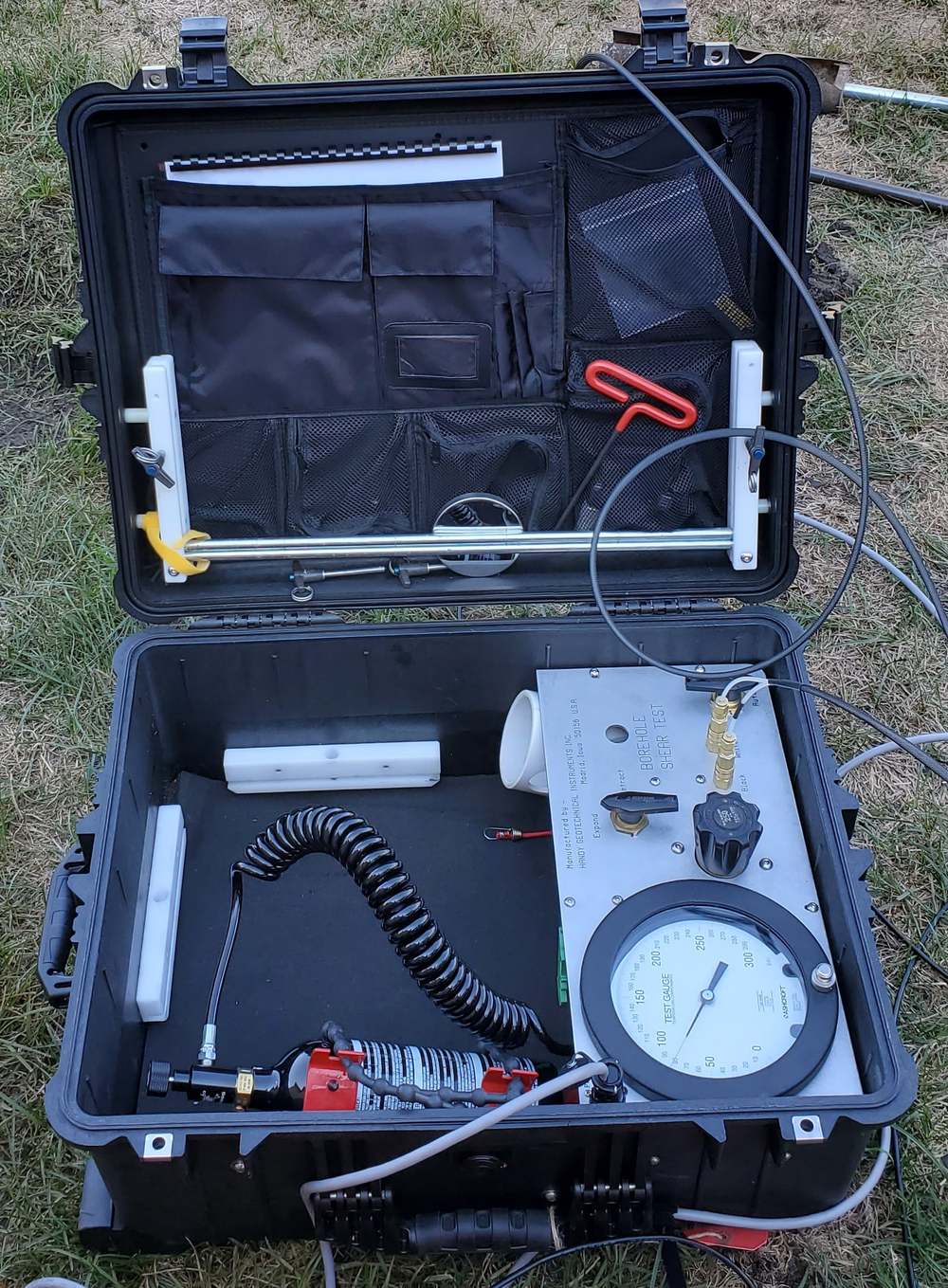

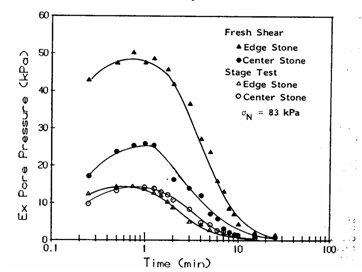

The BST shear head is opened with air or regulated gas pressure so plates press laterally into the soil. After 15 minutes the shear head is pulled upward. The same procedure then is repeated with progressively higher opening pressures and 5 minute waiting times.

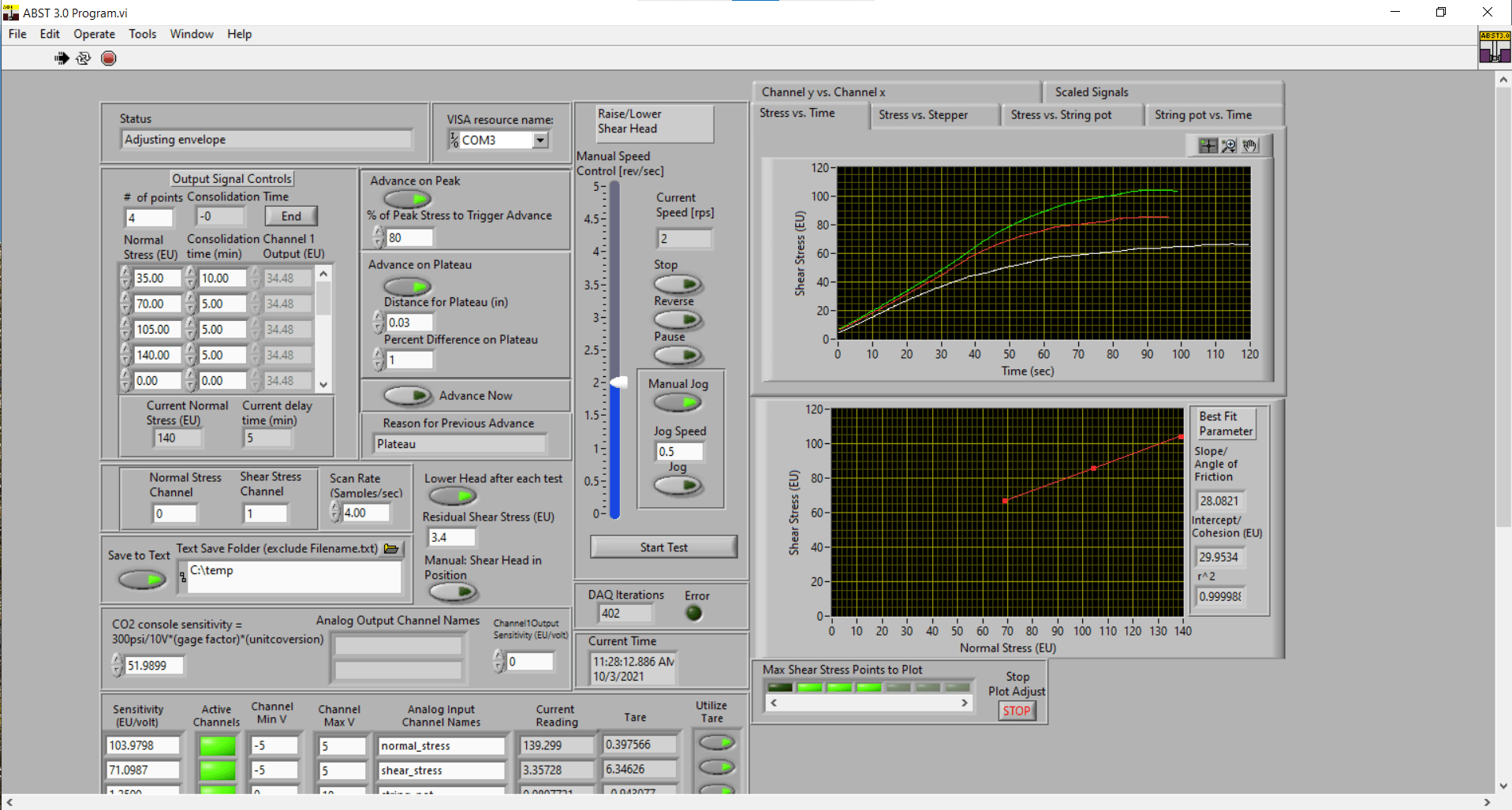

Automated Borehole Shear Tester

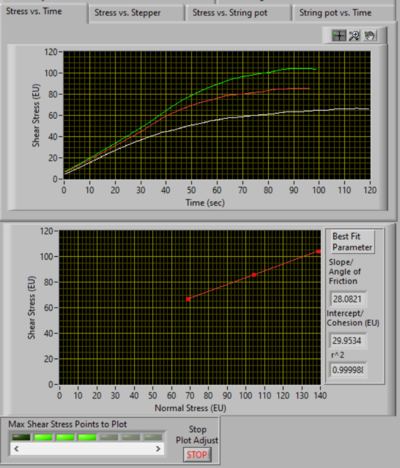

Full automation and one-button testing are an optional attachment for the BST. Applied normal stresses and consolidation times are preselected, shown in a column at the left of the laptop screen. Stress-deflection and shear envelope graphs are drawn as a test proceeds, and cohesion, friction angle, and R2 values are automatically calculated, This test is in glacial till. USA only.