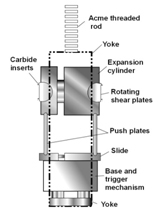

Rock Borehole Shear Tester

The Rock Borehole Shear Test was developed as a spin-off from the Borehole Shear Test described on another page.

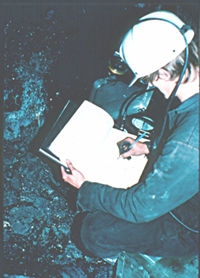

Major advantages are speed and the ability to test rocks that are too weak or fractured to core. Test removes bias to the unsafe side caused by testing only surviving sections of rock cores.

Facts about the RBST:

- Shear plates rotate to engage uneven rock surfaces; carbide teeth bite into the rock.

- Works in 75 mm (3 in.) cored or pneumatically drilled holes.

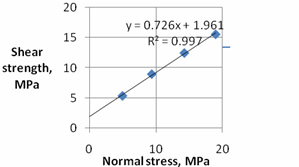

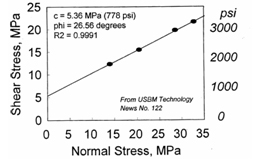

- A Mohr-Coulomb failure envelope usually within 20-30 minutes after a hole is drilled.

- Maximum recommended stresses are 12,000 psi normal and 5,000 psi shear (80 and 35 MPa).

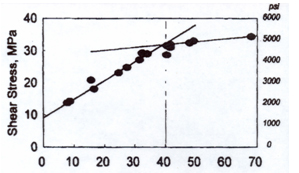

- Residual strength envelopes are easily obtained by continuing shearing after each break, and correlate with strengths along fractures and bedding planes.

The RBST was developed at Iowa State University for the U.S. Bureau of Mines. It is used for mine safety, tunnel and wall design In the U.S., Japan, Korea, India…